In the same way as for track maintenance, Plasser & Theurer places great importance on high-capacity, precision and reliability for track measuring. The clear processing and transfer of measured data is the ideal foundation for integration in the networks of the railways. There is a whole variety of options to carry out all required tasks as efficiently and therefore as economically as possible, ranging from the optimal processing of measured data to calculating track quality indexes up to the direct exchange of data with Plasser & Theurer track maintenance machines.

The track network is a dynamic, constantly changing system which is influenced by many different factors such as railroad traffic, type of subsoil, fluctuations of temperature, rainwater. Therefore, a good knowledge of the current state of the track by observing deterioration trends forms the basis for efficient planning of maintenance work.

In view of budget guidelines and lengthy track networks, this was often a task that was difficult to perform. However, with the help of a correctly chosen time as the intervention threshold in conjunction with constant analysis and documentation of the state of the track, it is possible to establish a solid starting point for this task.

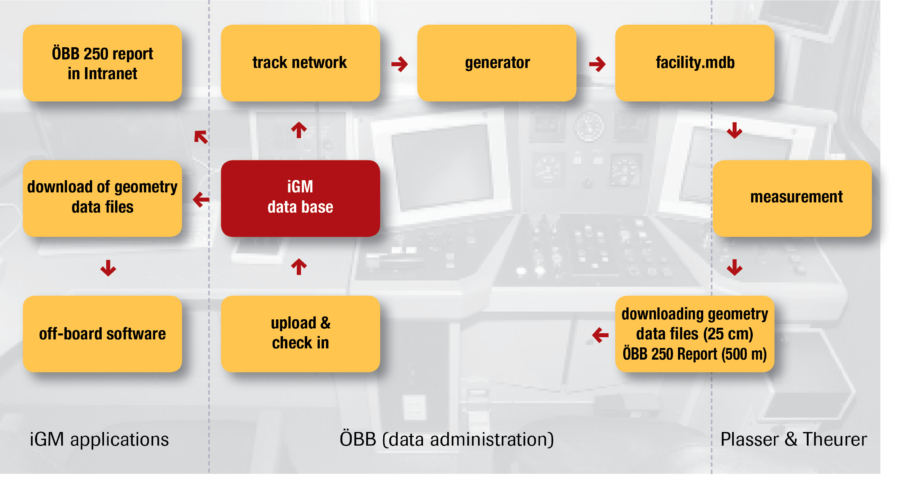

Austrian Federal Railways is a good example to show what advantages an extensive track geometry data base can bring. Here all departments involved can refer to a common pool of measured data taking into consideration the design track geometry. This facilitates the interaction of modern track geometry recording cars for regular monitoring of the state of the track with the demand-orientated maintenance planning, such as maintenance tamping or a large-scale track upgrading, and also including the acceptance measurement of the worksite. All those involved store their data in the data base.

Depending on their equipment and the requirements of the customer, modern track geometry recording cars built by Plasser & Theurer supply a wealth of data. The acquired data can be merged in a track geometry data base and are therefore available for long-term analysis. This provides the planning offices with a valuable tool. Rates of deterioration indicate which type of action would be the most suitable in order to restore the design track geometry and to retain it as long as possible.

Acceptance data of the Plasser & Theurer data recorder in the track maintenance machine for re-opening the line to traffic are stored in the data base again in digital form.

In this process, the engineering evaluation of collected measured data as an economic factor towards optimizing the maintenance measures performed in the entre track network is seen to be the key for a functioning system.

The first evaluation is performed during the measuring run by the district inspector responsible for the line. He observes the measured data processed in real time and the evaluations which give him an initial overview of the problem areas existing in his area of responsibility. In extreme cases he can give instructions immediately during the measuring run for action to be taken or for a line to be closed in particularly extreme circumstances.

Normally, however, the measured data are fed into the infrastructure data base. This is done either via WLAN during the measuring run or afterwards with the help of a data carrier, such as a USB memory stick. This ensures that the current data are immediately available in the network.

At ÖBB the regional inspector is also responsible for the evaluation of the measured data and he will then carry out a thorough analysis. Firstly, the problem areas are localized and then, particularly when the immediate action limit has been exceeded, visual inspection on the track will be planned and carried out which can be done quickly and effectively with the help of the data base. The reports made for this constitute an important additional source of information for the subsequent maintenance planning.

Further analysis is performed in cooperation between the local person responsible (district inspector) and an experienced specialist in the headquarters. With exact evaluation of the measured data, the defective areas and their possible causes are evaluated and a maintenance plan is established for the track network. Besides reports from line inspections and the single defect report, the data base provides them with a range of analysis tools such as the computer-assisted versine and longitudinal profile evaluation.

It is particularly important to re-trace the development of defective areas thus enabling important conclusions to be made on their origin. The data from other measurements, such as rail profile measurement or the images made by the video inspection system, supply additional information. The definite measures for the elimination of the track defects can be derived from these: in one case it may be sufficient to use a small tamping machine for spot defect elimination, in another case subgrade rehabilitation is needed, for which it will be necessary to give the order for further investigations such as taking ballast bed cross-section samples.

With the help of the infrastructure data base, the planning of all these measures is transparent and absolutely re-traceable. This means it is also possible to obtain finished maintenance plans from the respective departments for the post processing, such as cost planning, for example. At the end of this analysis process there will be clearance for the planned maintenance operations. Their implementation can now commence.

The ÖBB concept with regard to data access and data distribution differs considerably from that of most other railway companies. When tracks are measured, all the data are transmitted in full to an ÖBB infrastructure data base. The quality of the captured data is checked before storage. Verification of the data quality is extremely important for the evaluation.

The Infrastructure Service Centers (ISC) have developed decentralized operating plans with the help of the data base. The evaluation routines for NATAS (New Austrian Track Analyzing System) are also supplied from the data base. The measuring results are combined with the system data and other criteria. Historical data is superimposed over the current measurements in order to show the speed of deterioration (standard deviation). The results serve as a basis for maintenance programs (consulting for ISC).

For the comparison of several runs over the same section of track, a historical sequence of measured data is to be retrieved. At reasonable cost it is intended to keep available the data of the previous seven years. At present the data base holds a data volume of around 5 terabytes (= 5,000 gigabytes) with the data stored as measured values at intervals of 25 cm of track.

The regions (Infrastructure Service Centers) and all authorized users can access the data via the ÖBB intranet and via a geographical information system. The data are simple to find and to consolidate (displaying not every 25 cm but every 500 m for example) and can be aggregated subsequently to enable statistical evaluations to be compiled.

In the preparation of maintenance tamping the EM-SAT supplies the required values for efficient worksite planning. The data gathered by the EM-SAT are compared with the design track geometry in order to calculate the amount of ballast required. With this information, track tamping machine, ballast plough and stabilizer can perform their work without delay. In worksite operation the EM-SAT supplies the values for every operation of the track tamping machine in order to restore the design track geometry after track renewal and subgrade rehabilitation work or to adapt it if necessary. The EM-SAT can also be used for measuring tracks where the design track geometry is not known. The EM-SAT system has the great advantage that it works independently of the tamping machine and offers the operating staff a safe working environment. The integrated fixed point measurement saves a separate stage of work.

The Plasser & Theurer EM-SAT system has established itself internationally as a standard process for mechanized surveying.

One of the most important advantages of surveying using the EM-SAT is best possible planning of track maintenance. The prepared correction data are passed over to the machine staff of the Plasser & Theurer tamping machine. The data are entered into the ALC automatic guiding computer and displayed. The tamping machine now works off the correction data while the ALC takes over the comprehensive and automatic control of the measuring systems.

The measuring systems and the electronic recording unit of the tamping machine or the dynamic track stabilizer take over the measurement and recording of the corrected track geometry. These data are used for the acceptance of the work performed and are also sent back to the infrastructure data base. There they are available for a comparison with the acceptance regulations and for further evaluation.

This completes the networked measuring technology. The goal of raising the quality of the entire track network has been achieved.

THE GOAL OF RAISING THE QUALITY OF THE ENTIRE TRACK NETWORK HAS BEEN ACHIEVED.