These options make it easy to select the right vehicle with suitable measuring equipment. Common to all models is the high-quality mechanical engineering in conjunction with the latest measuring technology.

To measure, record and analyze track geometry, the standard measuring equipment of every Plasser & Theurer produced track recording car is the Plasser & Theurer non-contacting inertial navigational track geometry measuring system. This is a measuring system with integrated GPS navigation and the dual optical gauge measuring system OGMS.

The choice of the ideal track recording car depends upon the technical and commercial requirements in coordination with user-orientated fittings.

Vehicle design and fittings reflect the proven Plasser & Theurer quality. These series-built vehicles also meet the safety requirements specified for rail traffic. For design and construction mainly standardized construction elements are utilized. All vehicles are fitted with low-emission diesel engines and two 2-axle bogies and with either one or both bogies driven depending on the machine model. The measuring systems can be mounted on either of the bogies.

The bogies utilized are a Plasser & Theurer development and were designed especially for high axle loads and speeds of up to 200 km/h.

The engine outputs range from 190 kW on the EM30 weighing 21 metric tons to a total engine output of 1180 kW on the EM160 weighing 80 metric tons. Self-propelled cars offer independent use and flexibility in operation.

All Plasser & Theurer track recording cars can of course be placed in train consists. For special track situations, the vehicles can also be designed for narrow gauge or wide gauge. Diesel-electric generator sets provide the power supply on board, additionally an uninterruptible power supply unit is installed to protect the measuring systems and data processing systems.

To gain space and at the same time lower axle loads, large vehicles can be designed in two sections as “tandem vehicles” (EM140T and EM160T). This also allows bigger measuring cars to travel on secondary lines with low permissible axle loads and therefore to measure the entire network with one measuring car.

Plasser & Theurer track recording cars measure the quality of the track geometry, the rail and the catenary wire with high accuracy, and provide valuable video images of the track surroundings, the catenary wire, and the rail and tie conditions. Acceleration measuring systems record the ride quality, allowing conclusions to be drawn about track defects and wear patterns. The measurements and recordings for the regular inspection of the track, the rail and the catenary system are carried out simultaneously during one measuring run. The standard track geometry measuring system is the base system on all recording cars – all other installable measuring and video recording systems (see descriptions on pages 10 to 15) and any combinations of these systems depend on the vehicle size and the rack space available for the computers and analysis units.

The acquired measured data and video recordings are evaluated in real-time. The evaluations and exception reports are stored in digital form and are also available after the measuring run. At each of the evaluation terminals most of the measured data can be retrieved, displayed and printed out.

However, an additional, separate workplace is required to operate the ultrasonic rail flaw detection system.

For the average quota of planned measuring runs, it is necessary to select a measuring speed taking into account the length of the track network, volume of traffic on the line and the track recording cars available. Plasser & Theurer offers track recording cars self-propelled up to 160 km/h and towed up to 200 km/h.

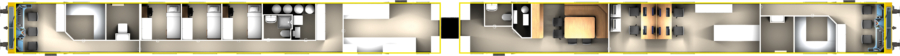

The vehicles are fitted with sound-insulated, air-conditioned cabins and driver’s control desks for both directions of travel. Depending on the size of the vehicle, additional facilities can be installed such as: conference corner, kitchen unit, sleeping compartments, washroom with shower and WC, workshop, etc.

Additionally to the standard crew operating the track recording car, regional track inspectors or other local staff may be on board for other operations. These personnel monitor the line and measured data from the perspective of the network operator. In the event of serious defects, they can implement immediate action such as speed restrictions or even track closures. Naturally, urban networks require other personnel than on inter-regional high-speed lines.

The mounting location of the drive engine has a great influence on the room layout. For reasons of space and comfort, it is preferable to install the engine below floor level. The choice of a slightly larger vehicle (longer distance between kingpins), which allows the engine to be mounted under floor, will provide a far more generous room layout. This allows more workplaces and measuring equipment to be incorporated and thus raises the cost-efficiency of each measuring run.