The ballast cross-section protects the track geometry against track buckling. Sufficient ballast must be available to counteract this danger, distributed as uniformly as possible along the length of the line. Track maintenance or the tamping of a newly laid track also requires sufficient quantities of ballast uniformly distributed in order to enable the track tamping machine to perform the required lifting values in a lasting way.

Producing the correct ballast cross-section, without surplus or lack of material, also brings economic benefits. Surplus ballast material, lying unused outside of the defined ballast bed profile, ties up financial capital.

Utilisation of these resources by modern ballast management systems reduces the amount of new ballast required – and thus the costs. Uneven ballasting can have a negative long-term effect on the track geometry. If there is a lack of ballast in some areas of the track, the tamping machine cannot carry out the specified lifting values to place the track in a firm position.

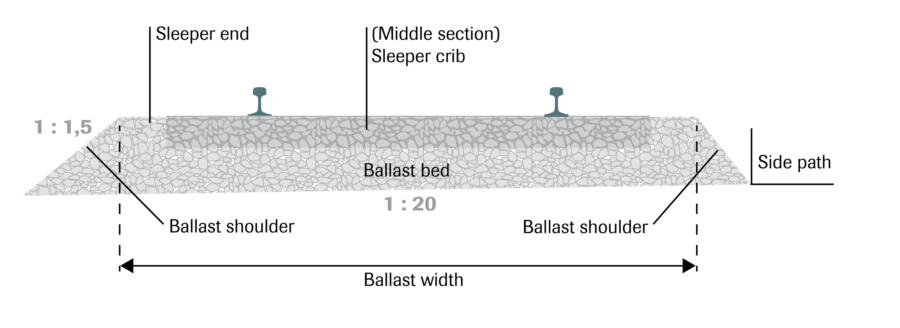

Sleeper end

(Middle section) Sleeper crib

Side path

Ballast shoulder

Ballast bed

Ballast width