What happens in the ballast bed during the stabilising process

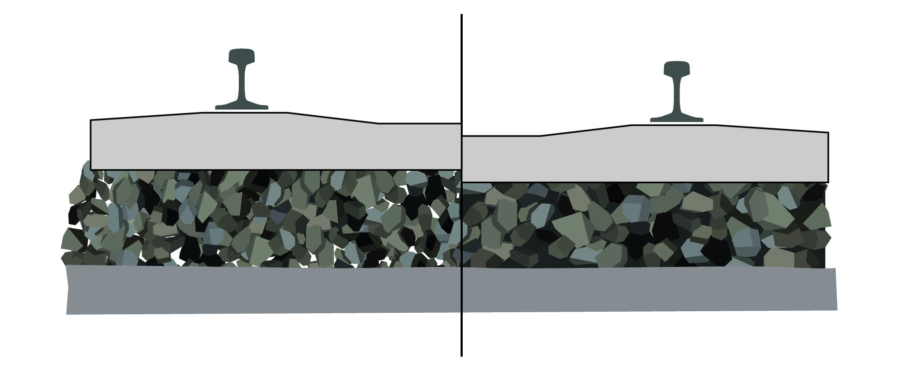

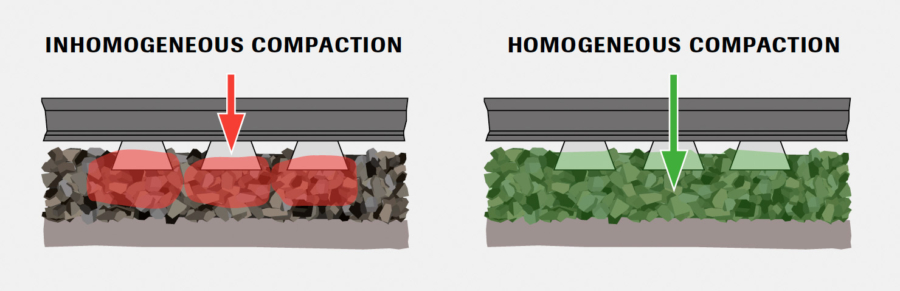

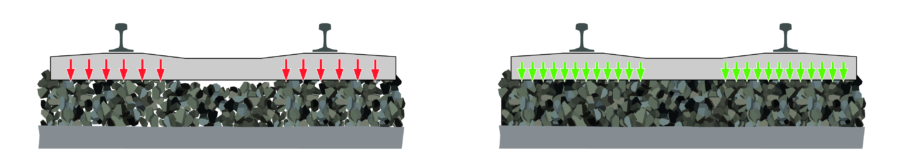

After maintaining the track by tamping, the ballast bed shows zones with varying degrees of compaction. After ballast bed cleaning or renewal, the ballast structure is not yet consolidated, and the ballast stones are not in optimal position to one another. That is why the ballast bed lacks density and stability that are necessary for firmly anchoring the track panel into the ballast bed.

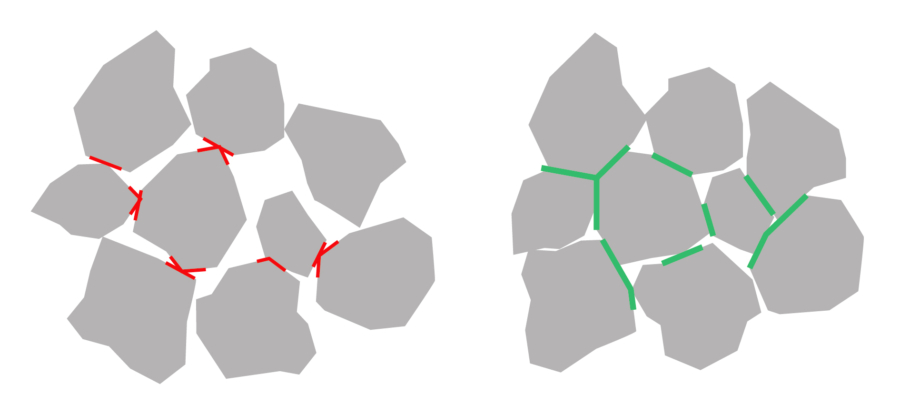

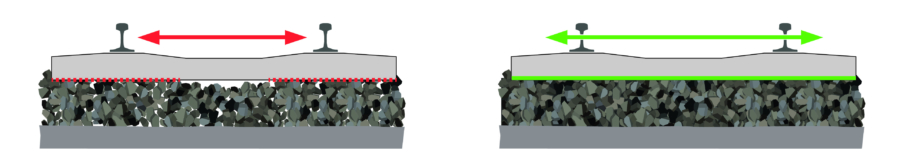

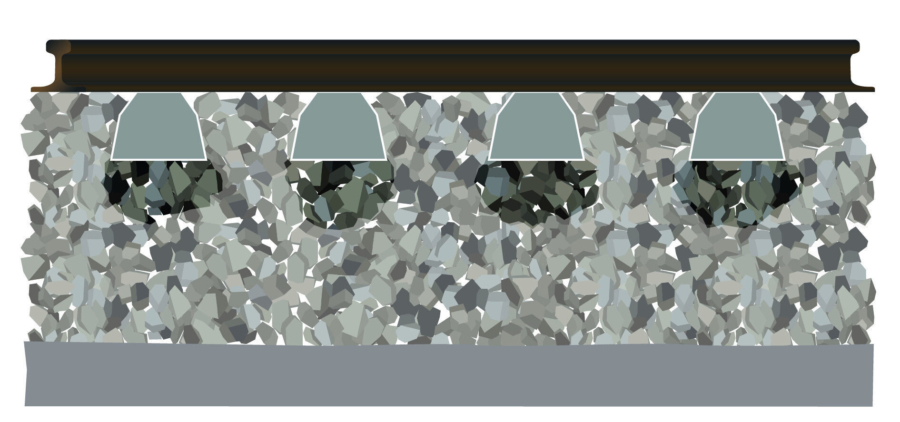

Via the track panel, the DGS introduces horizontal vibrations into the ballast bed. This causes the individual ballast stones to rearrange themselves closer to one another. The precisely controlled vibration in the natural frequency range of the ballast ensures that this happens with virtually no force (the ballast pressure is only about 8 N/cm²).