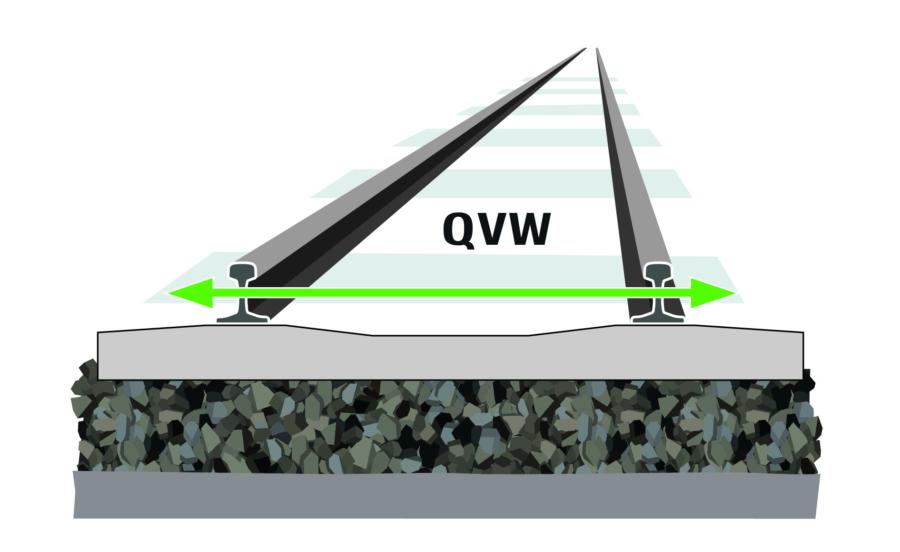

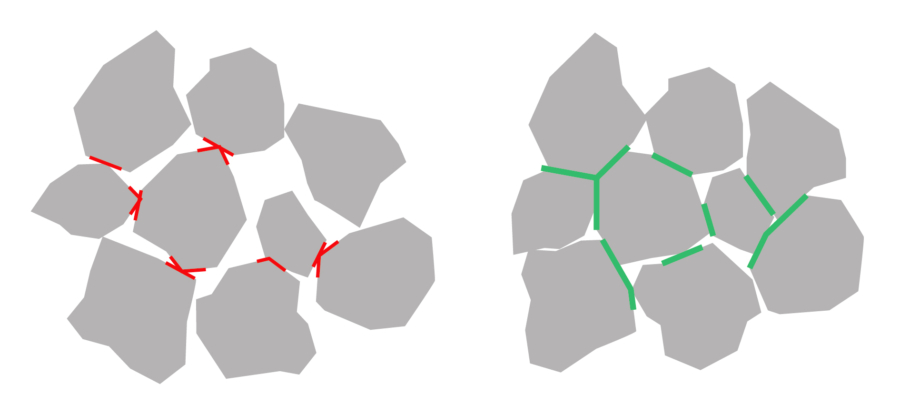

There is a direct correlation between resistance to track buckling and lateral track resistance (LTR). Due to thermal expansion, high temperatures lead to high longitudinal forces in the track. Train traffic causes additional horizontal forces, especially in curves and on high-speed lines or heavy-load lines. If the LTR is too low, the track panel buckles laterally as a result of these forces.

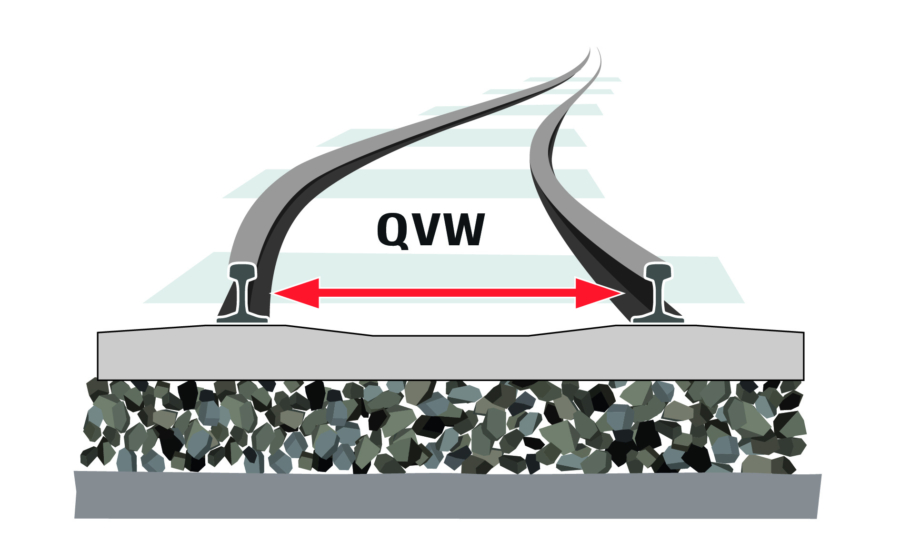

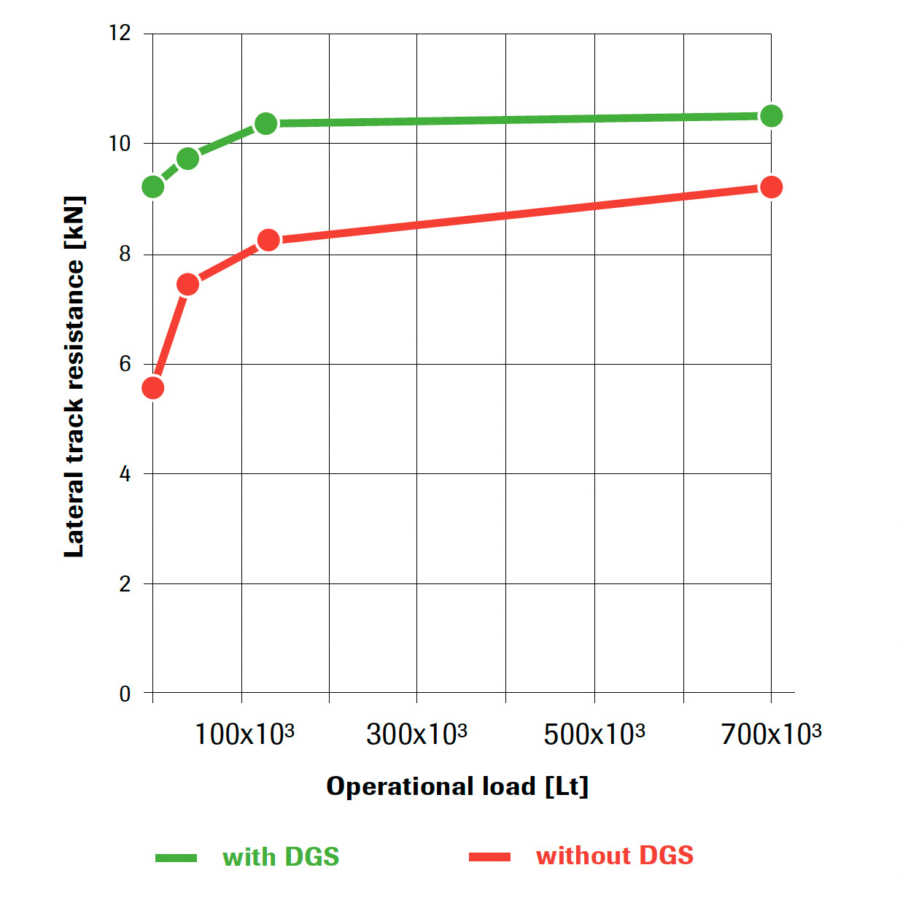

Manipulating the ballast bed during work on the superstructure naturally reduces the LTR. Without additional measures, the risk of track buckling increases significantly. As the LTR strongly depends on the degree of ballast compaction and the contact surfaces between sleeper and ballast, dynamic track stabilisation is the measure of choice for quickly restoring resistance to track buckling.

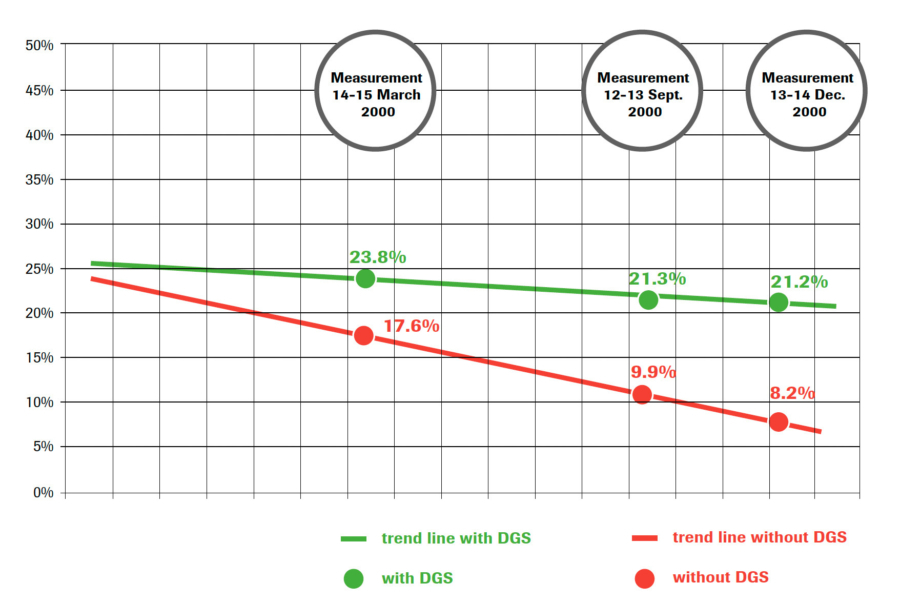

Source: Report 55624, Bundesbahn-Versuchsanstalt Minden/Westphalia

No more restrictions for tamping work during summers. Until now, it was only possible to use tamping machines on tracks for eight months out of the year. During the four summer months, the risk for track buckling after tamping work was too high. The DGS ensures the required LTR after a tamping machine has performed maintenance work. The DGS integrated into the machine produces the LTR and minimises the risk for track buckling. This reduces or even completely eliminates operational restrictions during summers while significantly increasing the machine’s cost efficiency and productivity.

“It is very important for us to eliminate working restrictions during summers. The integration of the DGS has revolutionised our maintenance plan. We can now design our operation schedule and the machine servicing plan more flexibly.” Yoshio Hasegawa, JR West

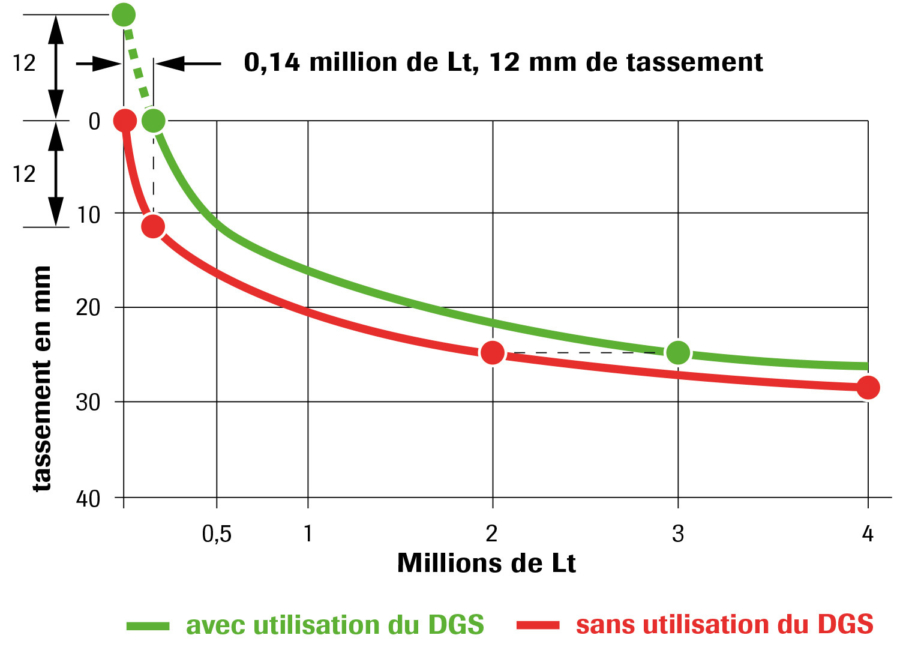

Every intervention into an existing ballast bed that has been compacted by passing trains reduces the compactness and homogeneity of the ballast structure and the stability of the track position. Therefore, after maintenance without subsequent track stabilisation, speed restrictions often are necessary until the operational load applied has caused the ballast to consolidate and the required LTR has been restored.

Dynamic track stabilisation anticipates the initial ballast consolidation that would otherwise have to be achieved through operational load. Studies have shown that this results in an immediate increase in LTR, equivalent to at least 100,000 Lt.

Source: ORE D117, PKP test series

Speed restrictions can be eliminated completely or significantly reduced in their duration. Immediately after maintenance, the section of track can be re-opened at the permissible line speed without any limitations to the line capacity. For this reason, dynamic track stabilisation has become indispensable, specifically for the construction, maintenance, and rehabilitation of high-speed lines.

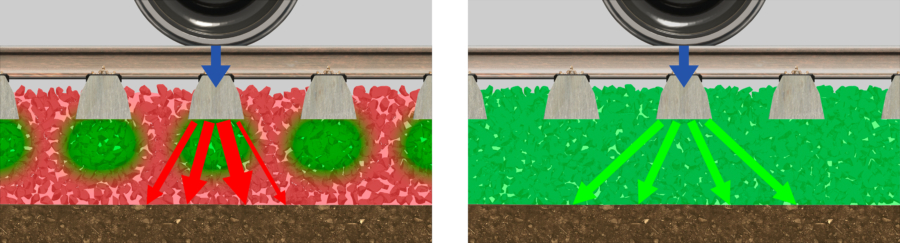

The vibrations transmitted to the superstructure by train traffic form a complex spectrum, both in terms of vibration frequency and amplitude, which acts on the track and the ballast with all its negative effects. The ballast stones rearrange themselves to a denser packing in an uncontrolled manner. This increases the stability, but also leads to uneven initial settlements.

Dynamic track stabilisation anticipates the initial settlements in a targeted and controlled manner. The precisely controlled vibration guarantees practically force-free and thus gentle compaction due to its frequency, amplitude, and direction (horizontal instead of vertical).

Significant cost and time savings thanks to the DGS According to DB Netz AG and Deutsche Gleis- und Tiefbau GmbH, the DGS represented a significant factor in process optimisation. Operated after sleeper exchange, the machine provided for a track load equivalent to 100,000 Lt., thus eliminating the usually required loading/train passages. The stability of the track geometry following dynamic track stabilisation allowed the line to be travelled at the maximum permissible line speed of 160 km/h.

(Quoted from the construction site report “Strecke Hamburg-Berlin wieder fit für den Hochgeschwindigkeitsverkehr”, published in “Der Eisenbahningenieur”, September 2009.

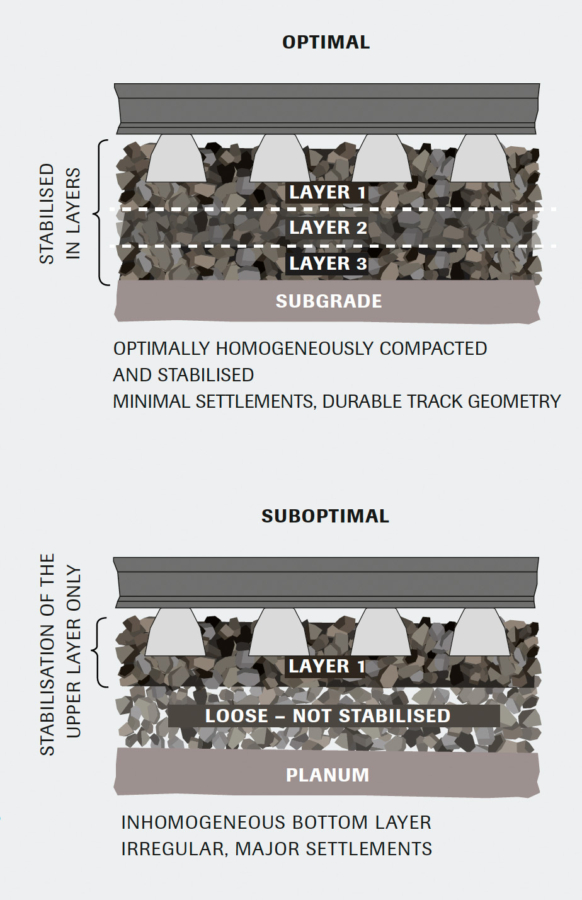

Dynamic track stabilisation as a part of work on the superstructure anticipates initial settlements in a uniform way. Combined with the homogenisation of the ballast structure, this leads to a reduction in uncontrolled, uneven settlements during train operation. As a result, the track geometry quality is maintained at a high level over a longer period of time.

In addition, a homogeneously compacted ballast bed transfers the dynamic forces of train traffic more evenly to the subgrade, which also positively affects the durability of the track geometry.

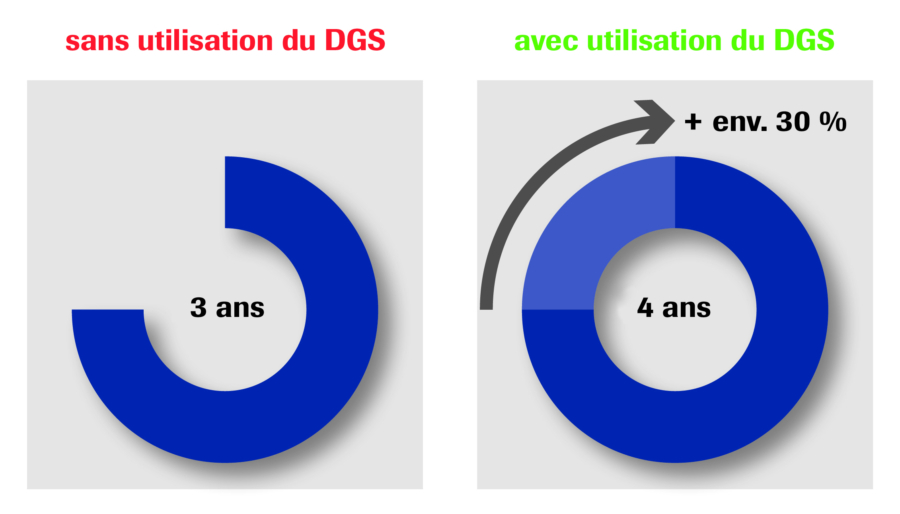

Experience has shown that dynamic track stabilisation results in intervals between maintenance measures that are up to 30 % longer.

The initial quality greatly influences the service life. That’s why homogenisation is a crucial step already during the construction of the ballast bed. Homogeneity is best achieved through layer-by-layer compaction; immediately after placing the ballast, each individual ballast layer is compacted using dynamic track stabilisation. Only in this way can the advantages in terms of extending the maintenance cycles and the track’s service life take full effect.

Conrail achieves significant cost savings. In the past, 72 hours of reduced speeds were required on maintained tracks. Thanks to the DGS, the speed restrictions now only apply to the first three trains travelling the track. In addition, the DGS has made it possible to extend maintenance intervals on main lines from three years to four years: this also has a significant economic impact on track maintenance.

„The use of the Dynamic Track Stabilizer allowed Conrail to reduce the length of time a slow order was required to be left on a tamped stretch of track from 72 hours to the passage of three trains. In addition, the use of the Dynamic Track Stabilizer, as indicated by data collected by the Track Geometry Car, has allowed Conrail to extend the surfacing cycles in many areas of the main lines from 3 to 4 years.“ (J. R. Clark, Seminar Brasilien, Juli 1995)

The operational loads introduced into the ballast by the sleeper are transferred into the subsoil via the contact surfaces of the ballast stones. However, this does not happen linearly, but via randomly formed force paths. The more homogeneous the structure and the higher the compaction density, the greater the number of contact surfaces both between the stones and between the sleeper and the ballast. The forces are thus dissipated more evenly, which reduces the mechanical load on the ballast structure and increases its service life.

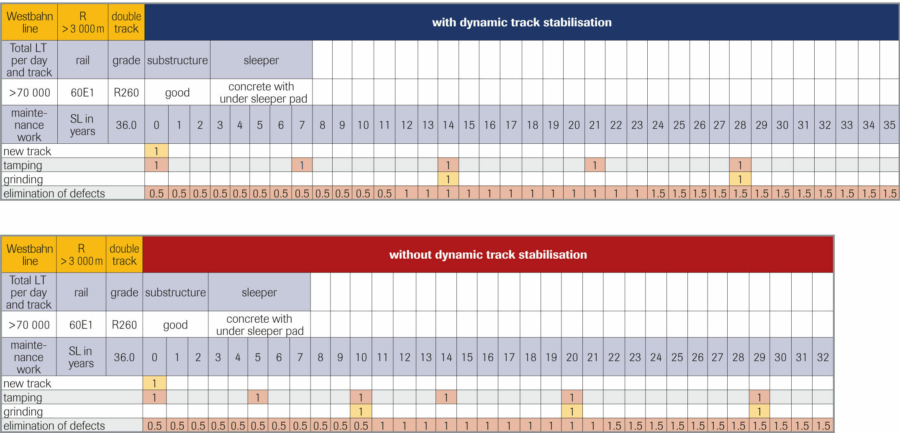

A comparative calculation using the example of the Westbahn line shows the benefits of dynamic track stabilisation with regard to the track’s service life:

Thanks to the use of the DGS, every interval between tamping can be extended by 30 % over the useful life without any loss of quality. This leads, without loss of quality, to an extension of the track’s useful life by 10 % (experience of ÖBB), i.e. the service life is prolonged from 32 to 35 years (Figure 8).

(Based on studies by Univ.-Prof. DI Dr. Peter Veit, Head of the Institute for Railway Engineering & Transport Economy at Graz University of Technology.