The vibration frequency greatly influences ballast behaviour. The DGS usually works at a frequency between 25 and 35 Hz, depending on the worksite and superstructure condition. This range enables optimal compaction while fully controlling settlement. It is possible to infinitely control the frequency via the rotational speed of the unbalanced masses.

In case of work units with constant imbalance, the rotational speed additionally affects the impact force thus influencing the vibration amplitude. By gradually reducing or increasing not only the load, but also the vibration frequency, the work units achieve smooth transitions at the beginning and end of construction sites and bridges. By contrast, work units with variable imbalance (Variable Impact Force) allow for impact force control regardless of the frequency.

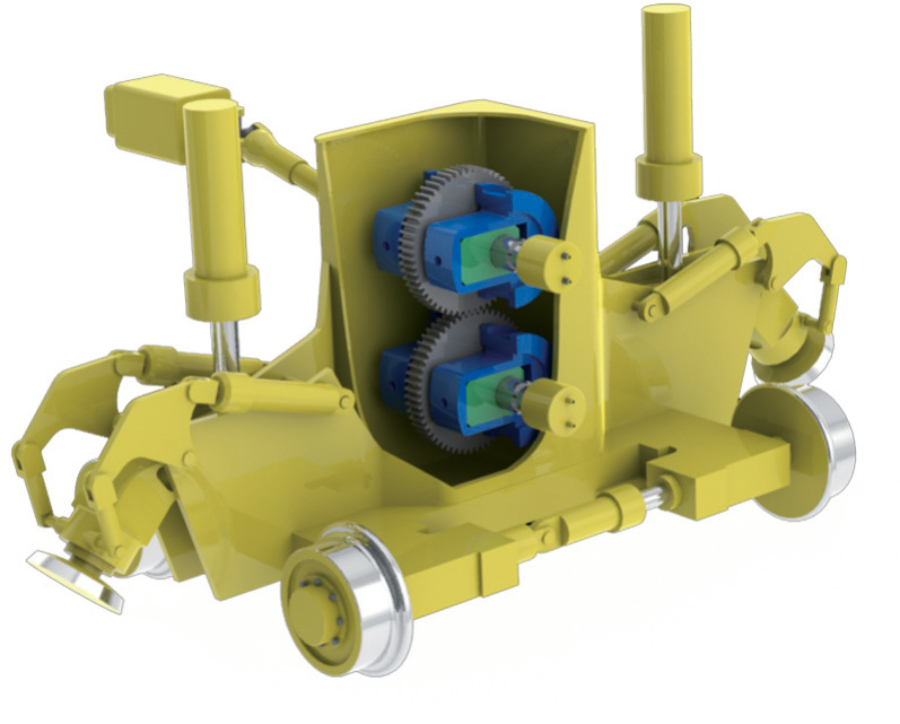

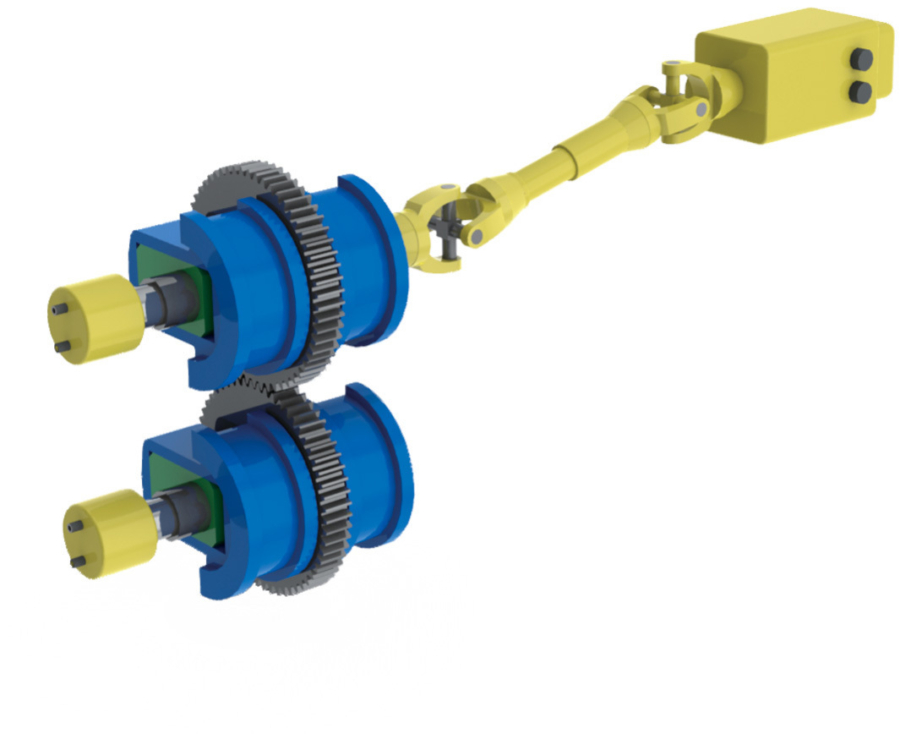

The dynamic impact force is the oscillating, horizontal force generated by the unbalanced masses. It affects the compaction energy introduced and is the one parameter that affects track settlement the most.

In case of work units with constant imbalance, the impact force can only be controlled via the vibration frequency. That is why the variable imbalance (Variable Impact Force) has been developed. It enables infinite control of the impact force between 0 % and 100 % regardless of the frequency. This is achieved via a hydraulically adjustable eccentricity of the unbalanced masses.

m ... Unbalanced mass [kg]

r ... Eccentricity [m]

f ... Vibration frequency [Hz]

Fdyn ... Dynamic impact force [N]

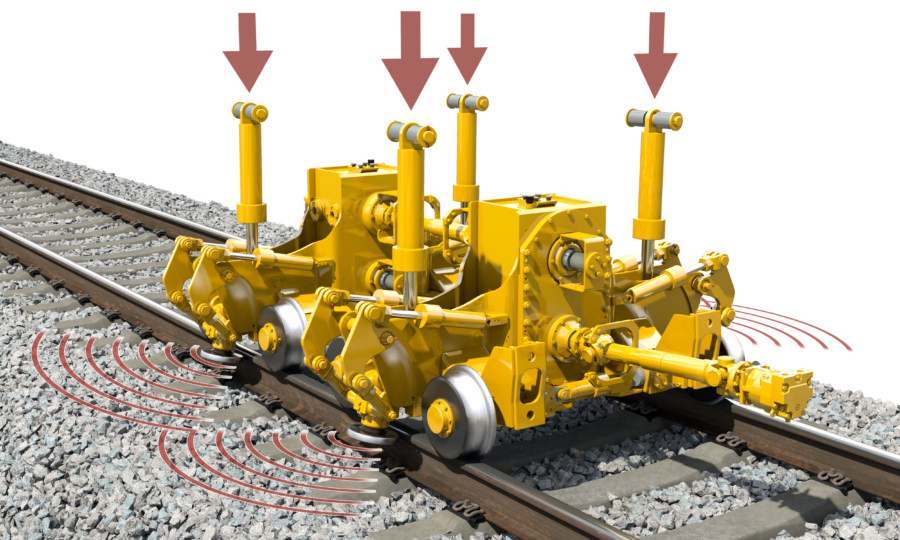

The vertical load transmits vibrations to the ballast bed and is a vital precondition for compaction effect as well as track settlement.

In order to correct any existing superelevation defects, it is possible to control the load cylinders in such a way that every rail is applied with the corresponding optimal load. The biggest machine type has a total load of up to 356 kN (36 t).

The first vibrations introduced have a far higher compaction effect than the following ones. Therefore, working speeds of up to 2,600 m/h are possible without significantly impairing the compaction effect. A double DGS unit is recommended for special conditions and for speed ranges from 1,000 m/h onwards, for example when using multiple-sleeper tamping units.

The DGS working speed mainly depends on other machines or work units, if present. Generally, a constant working speed must be ensured. If this is not feasible however, for example in case of turnouts or tamping obstacles such as signalling equipment, the Variable Impact Force enables a uniform compaction result despite varying speeds.